Startup Spotlight: medtech firm AliveCor’s KardiaMobile 6L

Medtech is increasingly big business, with the industry as a whole worth over $400bn in 2018-19. The industry incorporates a broad spectrum of companies. We’ve previously discussed the likes of MindMaze, the products of which are geared towards use in a clinical setting. Today we’re examining California-based company AliveCor, which is democratising medicine by bringing advanced heart monitoring technology to the home.

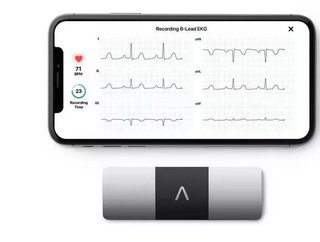

While we might be increasingly used to heart rate monitors on our phones or smart watches, AliveCor’s KardiaMobile 6L offers much more information in the form of a portable electrocardiogram, with the ‘6L’ referring to the six ECG leads it measures. While these can be viewed in the app, AliveCor also suggests sharing data from the FDA-cleared device with your doctor.

SEE ALSO:

AliveCor’s founder and Chief Medical Officer, Dr David Albert, told us Some of the possible diagnoses it is capable of making include “Atrial Flutter (abnormal heart rhythm), QT interval prolongation (the heart takes longer than normal to recharge between beats) and Left Ventricular Hypertrophy (the walls of the heart’s main pumping chamber thickens). Our goals for the long-term are to continue to develop diagnostic and monitoring solutions that are empowering patients and improving compliance.”

We checked everyone in the editorial department’s hearts, and are pleased to report no abnormalities (despite even the copious amounts of caffeine ingested daily). This was easily accomplished thanks to the app-based interface, which guides you through the process of putting your fingers on the two top electrodes, while putting the bottom electrode onto the exposed skin of your leg (we used our ankles).

More important than us, the company’s offerings have impressed investors, with AliveCor having raised almost $70mn total across a number of funding rounds, with investors including Japanese medical equipment manufacturer Omron.

AliveCor provided us with the KardiaMobile 6L for review

(Image: AliveCor)