Deloitte – Exponential technologies more important than ever for manufacturers

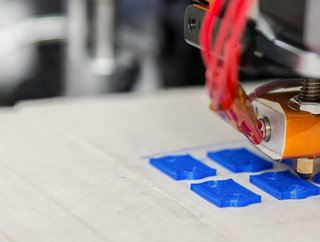

Manufacturers will need to embrace exponential technologies such as 3D printing, advanced analytics, modelling and simulation, and internet of things (IoT) platforms if they are to thrive, according to a new study published by Deloitte.

The Exponential Technologies in Manufacturing report, compiled in partnership with Council on Competitiveness and Singularity University, highlights opportunities for manufacturers to embrace exponentials to drive future competitive advantage.

It also reveals that talent continues to be a key competitive differentiator, with talent shortages a “critical issue across the globe”.

See also:

- 3D printing: from the automotive design studio to the factory floor

- How manufacturing companies can navigate digital transformation in 2018

- Read the latest issue of Manufacturing Global here

Among the statistical highlights include the forecast for artificial intelligence (AI), which as a market is expected to hit $72bn in 2021, growing at a rate of 55.1% a year. Blockchain is forecast to grow at 61.5% a year to 2021, reaching a value of $2.3bn.

Manufacturers are key users of these technologies, demonstrated by the fact that 86 of the top 100 R&D spenders are from the industry.

However, Deloitte does acknowledge a “sluggish” uptake in exponential technologies, which it puts down to a number of contributing factors, such as:

- Inertia of big manufacturing companies that stifles change, speed and agility

- Complacency, created by decades of success

- Fear of failure at all levels of organisations

- Regulatory burdens and high compliance costs

- Talent constraints caused by lack of availability, relative unattractive perception of manufacturing, and retirement of baby boomers and subsequent loss of knowledge

- Lack of management commitment and vision

The report is unequivocal in its conclusion that exponential technologies are more important than ever for manufacturers.

It states: “Exponential technologies are indispensable tools to help manufacturers address the bigger concerns and challenges that are part and parcel of transformation ushered in by Industry 4.0 and to transform into DMEs.

“These technologies grow and enable change at an accelerating pace, and are often used in conjunction with each other to fundamentally disrupt processes and industries—and create opportunities.”

Further, it found that its participant executives “overwhelmingly agree that being able to leverage innovative, exponential technologies is a matter of survival in the increasingly “disrupt or be disrupted” manufacturing industry”.