Materion’s materials meeting the demands of Industry 4.0

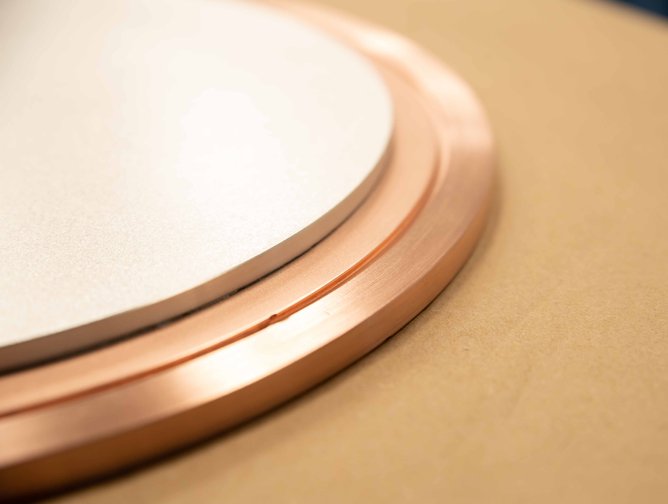

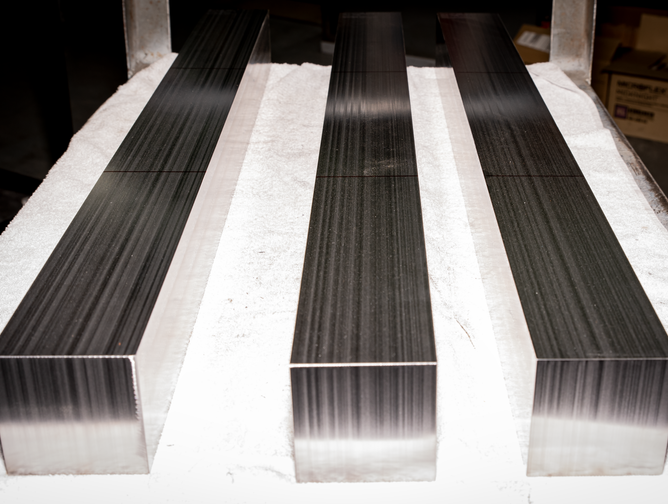

Though you may not be aware of using Materion products day to day, they are, in fact, essential to daily life, as the company provides a wide range of high-quality materials that enable technologies for a safer, more sustainable future.

From aerospace to clean energy, automotive to medical – and even in space – Materion's materials make possible many essential features of modern technology, including electrical connectors that remain reliable in harsh conditions, semiconductors that process data faster, and LEDs that are more efficient and produce better coloured light output.

Chris Roosien is Director of Infrastructure and Security Director at Materion, recently marking his first year working with the company. In the two decades prior to Materion, he held senior IT security roles in high-profile organisations, including Johnson Controls and Northwestern Mutual.

“I enjoy solving complex technology and business challenges,” says Roosien. “I also enjoy the opportunity to learn and continue to grow which I am able to do here at Materion. I find the ability to learn new skills and deploy new technology for solving complex challenges inspiring.”

Responsible practices for long-term growth

Today, Materion is committed to delivering its mission with a strong focus on Environmental, Social and Governance (ESG) practices, stressing the importance of alignment with responsible practices for the company's sustainable, long-term growth.

Materion's ESG approach centres on three pillars: governance and compliance; people development and diversity; and responsible environmental management. The company maintains strong governance and ethical operations while ensuring the privacy and data security of all stakeholders.

The company invests in its diverse workforce, providing safe work environments, professional development, tuition reimbursement, diversity programmes, expanded training, and certification opportunities to attract and retain top talent.

Materion is also committed to lessening its environmental impact and educating employees to be better stewards of the planet. Sustainability-based initiatives range from the efficient use of energy and materials to supplier selection based on ethical standards. The company is dedicated to making a positive difference in the lives of those it serves and has a long-standing legacy of upholding the highest ethical standards in pursuing business objectives.

Huge upside from digital transformation

As the manufacturing industry continues to evolve and become more intricate, the need to integrate and connect operations becomes increasingly crucial in gathering real-time, actionable data. This is commonly referred to as Industry 4.0 or Smart Factory, and Materion’s Information and Operational Technology teams have been collaborating with its businesses to develop a phased approach for building a digital foundation in its plants. This equips the company with real-time data to make informed decisions quickly and efficiently, ultimately benefiting both the customer and Materion.

“There is tremendous upside to digitally transforming our facilities and manufacturing processes to conduct business smarter with more efficiency and better customer care,” says Vinder Bhambra, Senior Director, Global Engineering. “Industry 4.0 gives us the ability to collect operating data automatically, without manual effort, and use that information to make faster, data driven, positive changes to our operations.”

With the right digital infrastructure, Materion says it can keep customers better informed by accessing better data more quickly. Real-time data provides the necessary tools to drive faster cycle times, reduce time-to-market, ensure on-time delivery, increase production capacity, and gain real-time business insights.

Leveraging real-time data allows the company to identify and address production or supply chain issues successfully, while eliminating paper-based processes and delivering digital manufacturing instructions to operators at each step. Improved quality assurance and 100% audit-ready compliance in manufacturing are achieved by digitally managing business rules and capturing operations and equipment data.

Industry 4.0 requires three basic elements: fast and secure digital connectivity on the shop floor, connected PLCs/automation or equipment involved in production, and a Manufacturing Execution System (MES) collecting data for use by operators, engineers, and leadership to improve production while providing end-to-end real-time business insights.

Materion recognises that many of its factories will require significant investment in digital connectivity to begin the transformation process. Its Operations Digital Strategy team includes representatives from all BU Operations Leaders, Information Technology, and Engineering shared services to prioritise and execute this transformation. While the implementation takes time, the benefits are tremendous, and this keeps Materion competitive in the modern digital era.

Finding partners is a question of trust

Roosien is addressing the constant challenge of marshalling resources and ensuring the right skill sets are in place to move projects forward: “That's always a big challenge. One thing I recommend is ensuring you find suitable partners. There are differences between suppliers, vendors, and trustworthy partners.

“We have challenges balancing operational needs with engineering and projects, and having that level of flexibility to work with my team and still deliver successful programs is really what sets them apart.”

A lot of this kind of industry work was paused for a couple of years during the pandemic, according to Roosien, and organisations are playing catch-up in many ways. “Making sure that you have an excellent prioritisation model is essential. What are the things on the list when something new comes in, what's the highest priority, what do I focus on and make sure team members know how to prioritise?

“A prioritisation list is not stagnant; it's going to change, so having the knowledge and ability to prioritise that on their own is even better. Equipping them with that is key.”

Materion has established partnerships along the way to successfully tackle international cyber threats with greater proficiency. You can find exceptional partners that helps companies with tools like Advanced Threat Detection and Response services that provide 24x7 US Citizen SOCaaS and Managed Detection & Response Platform access. Collaborations with companies that have these kinds of technologies allow Materion, and many other companies, to facilitate joint investigations of various kinds of threats through cloud security resources, threat intelligence, government and defence industrial base threat management.

Using a FedRAMP HIGH Ready provider with a strong compliance background is particularly beneficial because it enables companies like Materion to meet its CMMC and NIST 800-171 requirements, while protecting its sensitive data and critical assets from potential threats. By collaborating with companies that have these kinds of capabilities, it’s given Materion the necessary tools and resources to respond to a range of global threats swiftly and effectively. As such, collaborative IT partnerships for a global company like Materion bolster our cybersecurity stance, fulfil compliance objectives and combat any threats more efficiently.

Make sure you check out the latest edition of Technology Magazine and also sign up to our global conference series - Tech & AI LIVE 2024

**************

Technology Magazine is a BizClik brand